The pipe rehabilitation systems are used to renew circular and non-circular gravity flow and pressure pipelines up to 1400mm in diameter. We offer complete solutions for the total rehabilitation of sewer pipes, from lateral lining to sectional or point repairs.

Specifically, we offer three repair solutions:

- Liner Method

- Spray Coating Method

- Patch Repair Method

There’s no digging involved in this process, making it cost-effective and less disruptive method.

- A highly-trained technical team specialising in the use of materials and equipment

- All health and safety measures are followed

- The team is qualified to work in confined spaces

The method was developed to serve those seeking to solve problems related to ageing, deterioration, duct wear and can provide end-to-end solutions.

Process:

1

Pipe cleaning with special equipment to remove all the excess, dust or hazardous waste and achieve a smooth surface (cleaning chains and high-pressure water jetting machine)

2

Absorption of all impurities/residues

with a vacuum blower

3

Repair

Advantages:

- The lifespan of pipes is remarkably increased

- The pipe can be used straight away

- Rapid hardening and drying of the material

- Great adhesion

- Fixed coating surface

- Environmentally friendly and health-conscious materials

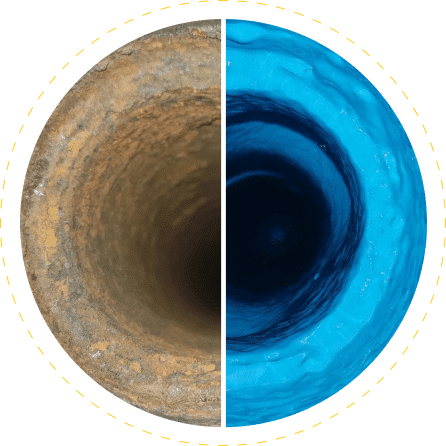

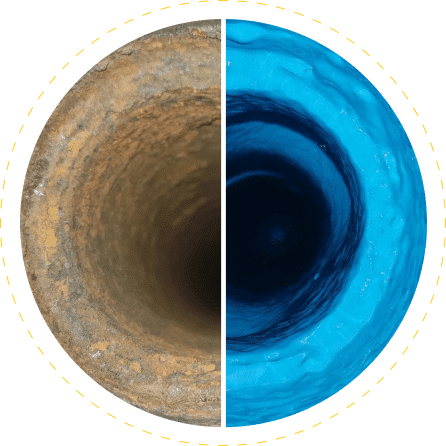

- High chemical resistance and high elasticity

The CIPP (cured in place pipe) technology is a trenchless method that rehabilitates ageing or damaged pipelines by constructing a new liner pipe inside an existing host pipe. A resin-saturated felt tube (liner) is inserted into a pipe with air pressure or water. CIPP can be applied to sewer, drain, and rainwater pipes.

Some of the conditions that require CIPP rehabilitation include:

- Broken pipes

- Infiltration

- Protruding connection

The materials used have excellent chemical and abrasion resistance and are very resistant in moisture.

Spray Coating is a new solution method to fix pipe-related problems. It can be used to renovate old or deteriorated drains and sewers from DN32 – 125 (1 ¼” – 5”). The coating applied provides a damp-proof, corrosion-resistant, wear-resistant, and non-corrosive lining.

Preparation:

- CCTV pipe inspection

- Pipe cleaning with the drill

- Flush out the pipe with water

- Dry the pipe

Benefits:

- Our equipment allows us to work more efficiently

- No mess, no fuss

- No dust and hazardous waste

- No need to move out until the pipe is fixed

- Cost-effective solution

Patch Repair is a fast method for repairing any defective parts in the pipes. It’s a tested, on-the-spot reparation of the system. The durability of the fibreglass against corrosion is an excellent tool for repairing and sealing pipes from cracks, leaks, and corrosion. The Resin and Fiberglass provide unparalleled structural strength, while its thin, tapered profile and smooth finish help maintain or increase flow capacity.